testing hydraulic pressure|hydraulic pressure testing procedure : dealers Hydraulic Pressure Test Kit,600bar /8700psi / 60mpa 5 Gauges 13 Test Couplings 14 Tee Connectors 5 Test Hoses, Hydraulic Gauge Kit Sturdy Carrying Case for Mine Excavator Construction Machinery Ships. 3.9 out of 5 stars. 3. $158.99 $ 158. 99 ($41.84 $41.84 /10 Items) 20 de fev. de 2024 · Por Anna Luiza Santiago. Nota 10: Matheus Nachtergaele, o Norberto de 'Renascer' 20/02/2024 08h03 Atualizado há 6 dias. Presentear matéria. Nota 10: .

{plog:ftitle_list}

You’ve just discovered the biggest free online slots library available in Canada. Like thousands of Canadian players who use VegasSlotsOnline.com every day, you now .

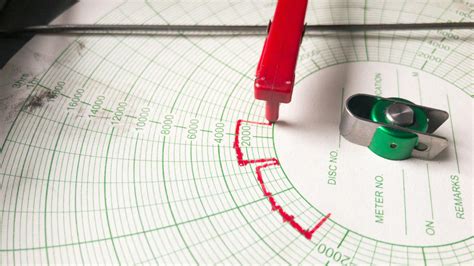

Common Hydraulic Pressure Tests. Pressure tests are performed on the hydraulic system to determine the integrity, the strength, the reliability of the system and to .Hydraulic Pressure Test Kit,600bar /8700psi / 60mpa 5 Gauges 13 Test Couplings 14 Tee Connectors 5 Test Hoses, Hydraulic Gauge Kit Sturdy Carrying Case for Mine Excavator Construction Machinery Ships. 3.9 out of 5 stars. 3. 8.99 $ 158. 99 (.84 .84 /10 Items)

In conclusion, hydraulic pressure testing machines are essential tools that play a crucial role in maintaining the safety, reliability, and performance of components across numerous industries.By understanding their working . Unlocking the Power of Precision: Hydrostatic Cylinder Testing ensures safety and reliability of pressure vessels. Explore the significance of ASME hydrostatic testing, its procedures, and compliance with regulatory .The final method is the engine oil pressure test, which involves connecting a pressure gauge to the engine to check if the lifters are receiving enough oil pressure. One of the most important factors to consider when testing hydraulic lifters is their ability to . The cylinder pressure test, designed to test the integrity of the piston seal and welds in hydraulic cylinders, pressurizes the cylinder during operation. Once the pressure has been applied, the cylinder is inspected for signs of leakage past the seal or welded parts.

B16.5 specifies hydraulic pressure test @1.5 times operating pressure rounded to 1 bar, for a duration of 60 seconds for fittings below 2″ NB. While testing liquid level gauges ( Small internal volume), the instrument is pressurized slightly MORE than 1.5, so that it would remain above specified TP.

Find out how you can study with us! https://certificate4.hydraulics.training/c4?r_done=1As we all know, hydraulic systems require a certain amount of pressur.Pressure Testing (Hydraulic Piping) Pressure testing is a process which is done to check for any errors in the installation or defects in the piping components. Basically the erected system is proof tested using the working fluid to something known as test pressure (usually 1.5 times the working pressure) and checked for leakages or pressure drop.

Hydrotest or hydrostatic testing is typically used for higher pressure components. Although water is most commonly used, other fluids such as oil or hydraulic fluid are sometimes used based on the materials under test and corrosion considerations. On the other hand, pneumatic testing is regularly used for lower pressure components. Air is .

The two main factors which affect the flow of fluids are pressure and density, so these concepts are also fundamental to the study of hydraulics. In this article, we will consider the key concepts of pressure and flow and how they apply to hydraulic systems – as it is the pressure and flow which enable work and motion to be accomplished.

Close ball valve (1) and center directional control valve (6). Note: it is assumed that the hydraulic power unit used to conduct the test has its own over-pressure protection - not shown in Figure 1. Record the respective pressure readings on gauges (3) and (4) and monitor any change over time.The hydrostatic test pressure for pipelines is designed based on the guidelines provided in the ASME B31.4 code for liquid pipelines and the ASME B31.8 code for gas pipelines. In general, the test pressure for the pipeline system is selected as .

This pressure testing method is observed as being unable to detect subcritical flaws in a system. These flaws require the systems to be exposed to higher internal pressure ranges to be detectable and measurable. Since hydrostatic testing depends on visual inspection and sometimes expansion measurement to certify the equipment or system safe for .Hydrostatic pressure testing, also known as hydrostatic testing or leak testing, provides a method for finding leaks or verifying performance and durability in pressure vessels. The hydrostatic pressure test is classified as one of LTI’s nondestructive testing techniques, meaning the sample is typically not harmed during the test.

Apr 15, 2021 / Ford 5000 hydraulic pressure. Thread Starter #7 . OP . OregonFord5000 New member. Joined Mar 29, 2021 Messages 8 Tractor 1969 Ford 5000. So I finally got all of my parts. While putting the Pto valve and support arm on the clutch last night, I found that the new PTO brake arm I got will not fit down on the outside of the clutch . Hydraulic Pressure Test Kit: This hydraulic test gauge kit for measuring pressure values in large hydraulic equipment systems. The 5 test gauges provide 3 pressure range options: 0-10 Bar/150 PSI, 0-100 Bar/1500 PSI, 0-250 Bar/4000 PSI, 0-400 Bar/6000 PSI, and 0-600 Bar/10000 PSI, catering to a wide range of hydraulic equipment with varying .

14.1 Overview of Pressure Test Requirements. 14.2 Hydrostatic Test. 14.3 Pneumatic Test. 14.4 Hydropneumatic Test. 14.5 Alternative Leak Test. 14.6 Sensitive Leak Test. 14.7 Jacketed and Vacuum Piping. 14.8 Initial Service Leak Test. 14.9 Closure Welds. 14.10 Requirements for Nonmetallic Piping.Pressure testing is a very small part of each of these standards. For example, ASME B31.1 – 2012 Power Piping covers the testing procedures for hydrostatic and pneumatic tests in only two pages. The emphasis is on the process of pressure testing, rather than on pressure testing safety. To bridge the gap, this publication focuses on safe workA proof pressure test is a type of non-destructive test where the component is pressurized to a determined pressure and held there in order to verify that the component can withstand the pressure. The pressure requirement is usually two to six times the normal operating pressure, and the failure criteria usually include leaking or deformation .

The 4.2 lb., Dusichin DUS-800 Hydraulic pressure test kit is a solid option that has a maximum working pressure of 9,000 PSI with three test hoses that are each 60" long, including 6 separate couplings. The Dusichin DUS-900 Excavator Hydraulic Pressure Test Kit has a variety of different features- including a maximum working pressure of .

Hydrostatic testing is a pressure-based technique used to test the integrity of piping systems, gas cylinders, boiler components, and all other kinds of pressure vessels. Hydro-tests are commonly done after repairs and downtime to determine if items will .Pressure tests are a non-destructive way to guarantee the integrity of equipment such as pressure vessels, pipelines, plumbing lines, gas cylinders, boilers and fuel tanks. It is required by the piping codes to confirm that a piping system is able to bear its rated pressure and it has no leaks. Pressure testing, also called hydrostatic testing, is carried out after the cooling or .

Hydro Testing Procedure Pre-Test Activities and Site Setup. Any item/part/component whose maximum permissible hydrostatic test pressure is less than the piping system is removed or isolated from pressure. Technicians install blind flanges, spade blinds, or closed position spectacle blinds to seal the system.The perimeter of the hydrostatic testing is quarantined, .The hydraulic test nipples, hoses and gauges will let you identify the operating pressure without a permanently installed gauge. The pressure testing nipples are designed to fit the world’s most common test-point system and are ideal for pressure check, lubrication and air bleeding in hydraulic systems.

Once the Cylinder is placed on the test stand and hydraulic lines attached, the cylinder will be cycled its full stroke a minimum of three (3) full cycles. The cylinder will be rejected if it functions erratically. Erratic function is excessive chatter, . Proof Pressure Test. The cylinder will be fully extended and pressure held at 2500 psi.Conveniently source pressure with a manual pump up to 300 psi, after that use an external pressure supply. For gas comparators use the fine needle valve or fine adjustment screw press to precisely meter the pressure. With hydraulic models use the screw press to source and fine adjust the pressure.All testing is performed under controlled conditions, following an approved test plan, and delivered with documentation and test records. The two methods of pressure testing we offer are: Hydrostatic testing up to 413 MPa (60,000PSI) using hydraulic oil, water/glycol and another client specified fluid

hydrostatic test pressure chart

hydraulic pressure testing standards

Resultado da ÚLTIMOS JOGOS Segunda Divisão - DOM 18/02/2024 Elche 0-0 Eibar Segunda Divisão - SÁB 10/02/2024 SD Amorebieta 1-0 Elche Segunda .

testing hydraulic pressure|hydraulic pressure testing procedure